Print Types

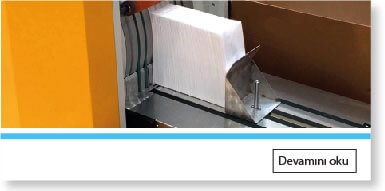

Flexographic Printing

Flexographic printing is a printing technique made with cliché. Flexo printing is a high printing technique. The job to be printed in this printing is at a certain height from the body of the mold. Because the cliché is flexible, it bends easily. The cliché is mounted on its cylinder with double-sided tape in the flexographic printing technique. The ink reservoir delivers the ink to the Anilox (screened) roller. The anilox roller touches the higher parts, and the higher places get ink. The image is transferred onto the substrate passing between the die roller and the printing roller.

Papirus produces your work up to 8 colors with flexographic printing. We use solvent-based paints. Solvent-based paints dry faster than water-based paints, and we deliver your orders in a shorter time.

Flexographic Printing Preferences Reasons

• Flexo provides good print color consistency.

• Flexo printing is good on rough surfaces.

• Flexo printing offers a wide range of substrates, including lightweight papers.

• Flexo printing is faster than sheetfed offset printing.

•Since flexo printing machines are multicolored (6-8-10), they allow the use of more extra colors. It is especially preferred in packaging production.

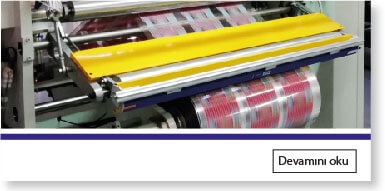

Rotogravure Printing

Gravure is one of the basic printing techniques used in printing. In this technique, steel cylinders are covered with copper and engraved according to printing. Copper is an easily processed material that wears out over time. The cylinder mold is hardened by chrome plating. Thus, the cylinder mold created is used with the same printing quality for a long time. During the printing process, ink fills the engravings on the rotating cylinder. As the paper passing from the warp bobbin to the winding bobbin passes through the roller, the paint in the engraving passes to the paper.

As Papirus, we can produce your works up to 7 colors with rotogravure printing.

Rotogravure Printing Preference Reasons

• As the tram points are closer and more intense, more precise and effective color separation is obtained.

• Rotogravure printing gives better results than flexographic in terms of printing print quality, ink saturation, and visuality.

• The same quality result is obtained in all prints in high circulation jobs.

• There is no blind ink setting as the roller rotates in ink. That is why it is clear, soft, and duplicated.

• The same cylinder mold can make millions of prints.

• Rotogravure plate preparation is expensive, and printing machines are expensive. For this reason, the intaglio printing system is not used for processes with a low number of prints. Rotogravure printing is high quality as well as economical printing for many processes.